MISFIT FLASH WEARABLE FITNESS TRACKER

Accelerated design for manufacturing helps a wearable lower costs and increase profit.The sleek Misfit Flash is one of the most inexpensive multi-use wearables on the market. Small, loaded with features, and cased within an elegant, stylized design, it works as well in the office as it does at the gym.

The brains of the piece—held within the watch’s face—had originally been designed housed in a protective metal casing that proved costly to produce, and ate away at Misfit’s profitability.

With its design and development of a new, pliable plastic Misfit Flash watch face, Radius proved that the Misfit Flash would sacrifice nothing in design or functionality, yet would offer wearers a more flexible and waterproof solution, one that offered improved battery life with just a tap of the interface. Now more affordable to produce, the Misfit Flash offers new value to its wearers – and to Misfit itself.

Through a rigorous prototyping and testing process, Radius arrived at a production-ready solution for manufacturing. In just months, Misfit’s Flash was in production with a new extraordinarily light, sophisticated, and uniquely functional plastic housing equivalent to the aluminum Misfit Flash.

Reducing the Costs, Not Elegance and Practicality

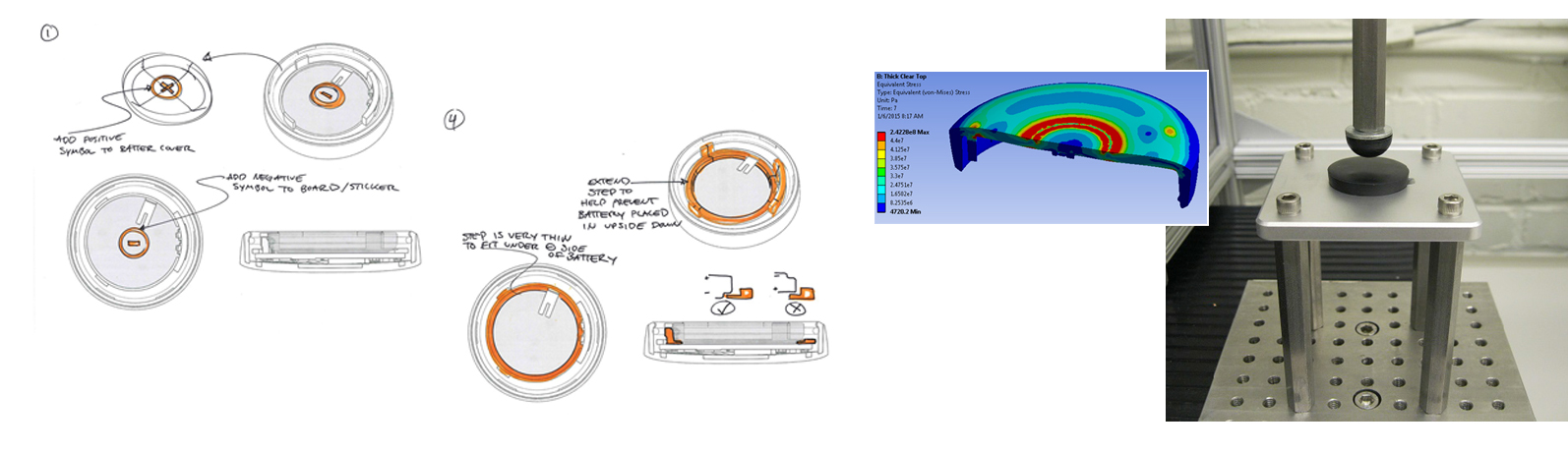

In order to replace Flash’s aluminum frame yet maintain the aesthetic of the device, Radius explored multiple plastic iterations, ultimately developing an injection molded-plastic solution that enabled flexibility and ruggedness within an aesthetic design sensibility.

Active Innovation Proves Less Can Mean More

Input from the research activities led to a stylized and discrete industrial design of a device housing that incorporated the research learnings, ensuring it met user needs, including patient-friendly features, such as a visual indicator, dose counter, and comfortable grip. In parallel with the external design of the product, Radius engineers developed the internal mechanisms required to achieve complete, robust function of consistent dose delivery.

The internal mechanisms were proven out early in the design process using step-by-step prototyping and proof-of-principle techniques. Radius utilized its implementation services to obtain complete injection-molded devices for further verification. The entire process was governed by Radius’s design control process in accordance with regulatory requirements.

Innovation. Made Possible. Made Better.

RELATED CONTENT

RELATED INSIGHTS

RELATED CAPABILITIES

WANT TO LEARN MORE?

Start a conversation with Radius to learn how we can help you take your Healthcare project to the next level.